1000's of successful projects delivered.

Enhar is proud to have worked with leading universities, governments, project developers and private companies around Australia to de-risk complex projects and raise the standard through excellence in project development, engineering, procurement and quality management.

Projects We're Proud Of

We have worked with universities, councils, business and project developers to deliver feasibility, tendering, design, planning, grid connection and quality management to their solar projects.

South Melbourne Market, City of Port Phillip

Feasibility (Solar, Battery, Embedded Network, EV), tender design, grid approval and owners engineer.

Independent Engineer: 14.5MW solar, 4MW BESS

Independent review of project engineering and construction quality through to commissioning phases. Site inspections and defects reporting.

Water Authority 770kW Ground Mount

Detailed design and grid connection management for 770kW solar PV system across three Water Treatment Plants.

4.5MW rooftop solar and carports

Owners Engineer for Solar Programs: rooftop, ground mount and carports. Feasibility, procurement management, quality control, superintendent

Clayton 1.01MW roof top solar, United Energy

Detailed design and grid connection management for 1.01MW solar PV system. 5 LV connection points on a HV supply.

Maintenance audit of 60MW solar farm

Enhar undertook a maintenance review of a remote 60MW solar farm in a dusty environment in Western Australia.

Yarra Ranges Council 4.5MW Solar Landfill Feasibility

Solar landfill feasibility study exploring how to transform unproductive land near landfill sits into renewable energy solar farms.

Solar PV Program (>3MW)

Owners Engineer for UoM >3MW solar program since 2015. Feasibility, design, tender management, quality assurance and asset management.

Electrical design of 2 x 5MW batteries on Tonga

Detailed electrical design of LV and MV components of BESS systems.

400MW Solar farm design and planning permit

400MW Solar farm design and planning permit.

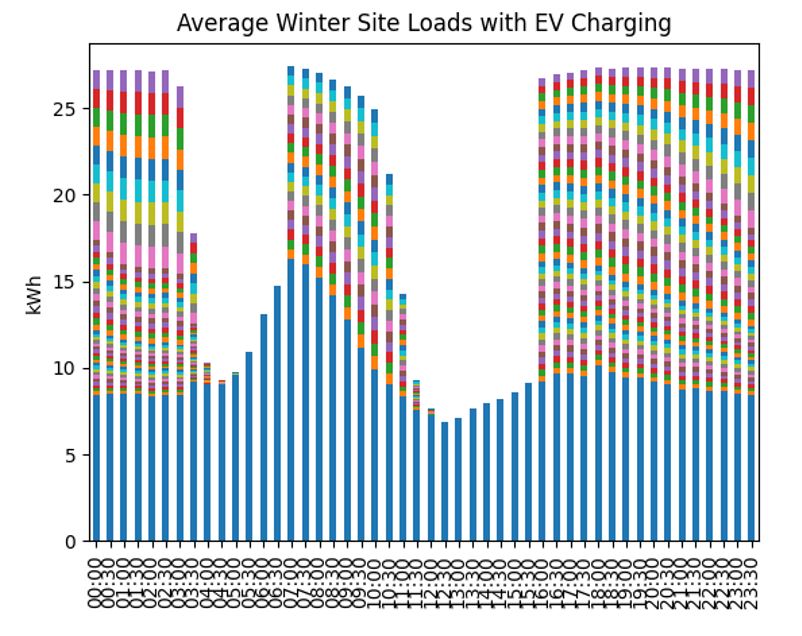

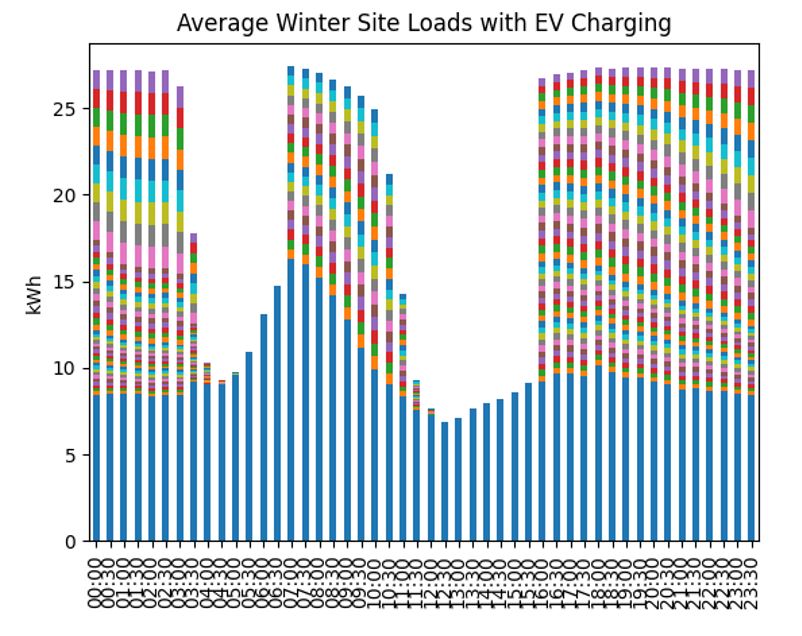

EV infrastructure feasibility modelling and design

EV Charging Infrastructure feasibility, fleet modelling and detailed design. Depot 112 Vehicles, Civic Centre 39 Vehicles.

4.9MW Longwarry battery land and planning permit

Winning a non-network solution EOI, securing land and planning permit.

University campus solar farm

Solar farm specifications, project coordination and grid connection modelling.

Condition, safety and performance auditing.

Condition, safety and performance auditing on 25 commercial solar PV systems, including creating a detailed asset register.

Brisbane Convention & Exhibition Centre 309kW

Feasibility, tender design, grid approvals and compliance engineer, for high profile inner city buiding.

EV Infrastructure Feasibility for Residential Stata Buildings

30 EV Charging Infrastructure Feasibility assessments for apartment buildings with up to 350 spaces, for facility/owners corporations.

Standalone Power System design for Telecom Sites

Site assessment, load modelling and detailed 'for construction' design of solar battery diesel for 50+ telecom sites.

LHAC: 6 Aboriginal Homeland Communities

Containerised Solar Diesel Hybrid System optimisation and design for 8 Aboriginal homeland communities in North East Arnhem Land and Kakadu.

Private hospital solar rollout (national)

Feasibility, detailed design, tender management and owners engineer for hospital sites in Vic, WA and NSW.

Owners Engineer Solar PV, Battery & EV

Working with Nillumbik Shire Council to deliver solar PV with storage and EV chargers, from feasibility to final commissioning.

Cardinia Childcare: Solar PV and BESS

Detailed design and Grid connection management for 2 x 100kW rooftop solar and 180kW/hr/90kW flow batteries.

Hepburn Energy - visual assessment for hybrid solar and battery planning permit

Community Solar farm required visual assessment to support its planning permit and community engagement.

Business case for large battery addition to 40MW solar farm

Modelling financial viability of large scale storage for arbitrage and FCAS.

Solar PV at school with complex wireless interlock

Creekside College 100kW rooftop solar with wireless interlock.

Commercial Power System Design for Jemena Sites

Detailed design 'for construction' and ‘as built’ of solar sites. Grid connection approvals.

South Melbourne Market, City of Port Phillip

Feasibility (Solar, Battery, Embedded Network, EV), tender design, grid approval and owners engineer.

Water Authority 770kW Ground Mount

Detailed design and grid connection management for 770kW solar PV system across three Water Treatment Plants.

4.5MW rooftop solar and carports

Owners Engineer for Solar Programs: rooftop, ground mount and carports. Feasibility, procurement management, quality control, superintendent

Clayton 1.01MW roof top solar, United Energy

Detailed design and grid connection management for 1.01MW solar PV system. 5 LV connection points on a HV supply.

Solar PV Program (>3MW)

Owners Engineer for UoM >3MW solar program since 2015. Feasibility, design, tender management, quality assurance and asset management.

EV infrastructure feasibility modelling and design

EV Charging Infrastructure feasibility, fleet modelling and detailed design. Depot 112 Vehicles, Civic Centre 39 Vehicles.

Condition, safety and performance auditing.

Condition, safety and performance auditing on 25 commercial solar PV systems, including creating a detailed asset register.

Brisbane Convention & Exhibition Centre 309kW

Feasibility, tender design, grid approvals and compliance engineer, for high profile inner city buiding.

EV Infrastructure Feasibility for Residential Stata Buildings

30 EV Charging Infrastructure Feasibility assessments for apartment buildings with up to 350 spaces, for facility/owners corporations.

Standalone Power System design for Telecom Sites

Site assessment, load modelling and detailed 'for construction' design of solar battery diesel for 50+ telecom sites.

Embedded Network Feasibility for the City of Greater Bendigo

Establishing regulatory, technical and financial viability of a smart embedded network.

LHAC: 6 Aboriginal Homeland Communities

Containerised Solar Diesel Hybrid System optimisation and design for 8 Aboriginal homeland communities in North East Arnhem Land and Kakadu.

Private hospital solar rollout (national)

Feasibility, detailed design, tender management and owners engineer for hospital sites in Vic, WA and NSW.

Owners Engineer Solar PV, Battery & EV

Working with Nillumbik Shire Council to deliver solar PV with storage and EV chargers, from feasibility to final commissioning.

Cardinia Childcare: Solar PV and BESS

Detailed design and Grid connection management for 2 x 100kW rooftop solar and 180kW/hr/90kW flow batteries.

Solar PV at school with complex wireless interlock

Creekside College 100kW rooftop solar with wireless interlock.

Commercial Power System Design for Jemena Sites

Detailed design 'for construction' and ‘as built’ of solar sites. Grid connection approvals.

Independent Engineer: 14.5MW solar, 4MW BESS

Independent review of project engineering and construction quality through to commissioning phases. Site inspections and defects reporting.

Maintenance audit of 60MW solar farm

Enhar undertook a maintenance review of a remote 60MW solar farm in a dusty environment in Western Australia.

Yarra Ranges Council 4.5MW Solar Landfill Feasibility

Solar landfill feasibility study exploring how to transform unproductive land near landfill sits into renewable energy solar farms.

Electrical design of 2 x 5MW batteries on Tonga

Detailed electrical design of LV and MV components of BESS systems.

400MW Solar farm design and planning permit

400MW Solar farm design and planning permit.

4.9MW Longwarry battery land and planning permit

Winning a non-network solution EOI, securing land and planning permit.

University campus solar farm

Solar farm specifications, project coordination and grid connection modelling.

40MW solar with 40MW/80MWh battery, Queensland

Hepburn Energy - visual assessment for hybrid solar and battery planning permit

Community Solar farm required visual assessment to support its planning permit and community engagement.

Business case for large battery addition to 40MW solar farm

Modelling financial viability of large scale storage for arbitrage and FCAS.

Have a lot of free roof space?

Building a solar farm?